| Planning

&

Reference Images Production Photos The Model on set & Art Department Pictures            |

Yes,

we can do it. Now,

what's the problem?

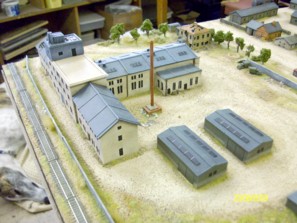

At the beginning of august 2009 we had a telephone call from the art department at Battleplan Productions who were working on a remake of the Sam Peckinpah film “Straw Dogs”. The film was due to start shooting at the end of August and there was a problem with one of the main props. The main character in the film (played by James Marsden) is a screenwriter working on a script for a film about the Battle of Stalingrad, and the art department needed a model of the Grain Elevator as a display piece for the character's study. The art department had tried several model making/architectural modelling companies in the USA but with no luck. Then, while searching the web, they found the 1/300 model Grain Elevator on our web site. They phoned us up, explained that they had a problem and could we help? You

want it when?

We had several discussions over the phone to establish the requirements of the model but it was not until the historical advisor joined in the discussions that we were able to finalise the details.

The shipping deadline was our main problem. We knew that we could design and build the model but completing the task in two and a half weeks was a bit more problematical. However, we took a chance and said of course! No plan survives contact

with the

technical advisor!

We had sufficient background knowledge of the battle and the grain elevator to allow us to start our initial planning but fortunately the historical/technical advisor Russ Schulke was in a position to send us a wealth of reference materials via e-mail, including aerial photographs taken by the Germans and Soviets during the battle, modern photographs of the area and grain elevator, and a number of maps and plans of the area. Russ had also tinkered with some of the aerial photos and overlaid them with a grid and also used computer graphics to highlight the buildings and structures around the grain elevator. These were to be of immense value and saved us a lot of work when designing the layout and buildings. Once we had the basic requirements we were able to start planning the construction. The priority had to be designing the layout and preparing the grain elevator model so that it was as accurate as possible, while keeping the shipping deadline firmly in mind. The initial images sent to us by the technical advisor allowed us to make a start on the layout while the he worked on more detailed studies of the buildings etc. Fortunately Barrie, one of the TimeCast team, had spent several years as an Imagery Analyst/Air Photo Interpreter in the British Army and was experienced in working with aerial imagery. We were thus able to make very good use of the aerial imagery to determine the details of the model. As an example, there were several industrial chimney's which were shown on some oblique photos but which were not visible on the vertical overhead images. By examining the shadows cast by the chimneys in the oblique photos we were able to determine the approximate time of day when the photo was taken and to subsequently calculate the approximate height of the chimneys. Careful examination of other photographs allowed us to determine the type of ground cover (short grass, long grass, bare earth etc) and to plot the positions of individual trees and bomb craters. OK,

where do we start?

Fortunately the area around the elevator is flat (this was confirmed by the technical advisor who has visited the grain elevator in modern Volgograd). This meant that we did not have to worry about contour work but could build straight onto the baseboard. In addition, we were able to use a lot of our standard 1/300 model buildings to bulk out the structures while we worked on the more complex models. We were also able to order substantial stocks of commercially available Z scale model railway fencing, tree armatures, foliage materials etc which saved a lot of time during the construction phase. In the case of the trees, hand built models would have looked better but we had to remember our deadline and the commercial items did save us a lot of time. The Grain Elevator. Although we already produced a model of the grain elevator after comparing it with additional reference material from the USA we determined that part of the model would require a substantial redesign to make it more accurate. This would subsequently take a day and a half to complete. There were also a number of industrial structures around the area which would need to be designed and built from scratch, using photos where possible with a bit of educated guesswork to fill in the gaps. The Railway Tracks. There were two sections of railway track to be modelled. The first was a spur line running along one side of the model, the other was a four track marshalling yard/loading area adjacent to the elevator itself. We considered using Z scale model railway track but we did not have time to lay and pin the track, or to add the required ballast, so we needed to find another alternative. Fortunately Irregular Miniatures produce 1/300 scale railway tracks, points and rolling stock. These did not need any assembly or pinning and we could use them straight out of the box. After a couple of phone calls and e-mails the helpful chaps at Irregular were able to send the materials we needed with delivery the following morning. Can

we fix it? umm......

After a couple of hectic days planning the model, clearing the workbenches, drawing up the plans for the new designs etc we were ready to start. The sequence of construction was as follows:

You stick it

together and I'll start painting stuff...

Construction started on the 8th of August, although some of the technical details were not actually finalised until several days later. The model was finished on the 20th of August and was packed and shipped on the 21st. The construction process was extremely involved and, during the early stages, it didn't seem as though anything was happening. However, as the model progressed and the buildings and structures were finished, detailed and added to the base we began to see the model coming to life. At a rough guess the model took approx 240+ man hours to make. This meant a lot of very busy 12-14 hour days and little time off in order to meet the deadline! However, not only was the model a real challenge to our skills, it was also a very satisfying project to work on. It was fascinating to look at the reference photos and to see the grain elevator and its surroundings come to life as work progressed. In order to keep the film company updated with our progress we took a number of photos of the model at the end of each day and e-mailed them to the art department each night. By the time we were halfway through construction we had members of the art department queuing up to see the new photos each morning. We're

going to need a bigger box...

We had to build a shipping container for the model. This was built oversized to allow plenty of room for packing material. The finished model was quite heavy and the size of the container meant that it required a fork lift truck of several people to move. This gave us confidence that the model would not be thrown around too much in transit and should arrive safely, which it did - although we had a nervous couple of days waiting for confirmation of its safe arrival in the States. The model itself was originally intended to have been smashed during filming and we were quite looking forward to seeing it destroyed on the big screen. However, Russ the technical advisor offered to waive his fee if the film company to let him have the model on completion of filming and it now resides in his personal collection of Stalingrad memorabilia. For film buffs here are the details of the movie: Straw Dogs (2011) Director: Rod Lurie Starring: James Marsden, Kate Bosworth, Alexander Skarsgard Full details on IMDB here: Straw Dogs (2011) |

|

Please

note that TimeCast models are not toys. They may contain small

pieces, or white

metal parts, which may cause a choking hazard and are therefore not

suitable

for children under 12 years. All images and models shown are copyright TimeCast and/or the the respective Manufacturers and may not be copied or reproduced without the appropriate permission. |

|

| Terms & Conditions Contact TimeCast Modelling Tips Gallery Page Distributor |

TimeCast Unit 11N, Centurion Park, Kendal Road, Shrewsbury, SY1 4EH, England Tel: (0044) 01743 465676 E-mail: sales@timecastmodels.co.uk |